Yarn producer, Aquafil has designed the ECONYL® Regeneration System, which enables Nylon 6 waste to be regenerated into new Nylon 6 with no loss of quality. Key to success is the Reclaiming Programme, an essential tool to facilitate a reverse supply chain and ensure reliable materials inputs.

Aquafil Group have a strong heritage in effective resource management, in making nylon yarn for carpets and apparel. For over 50 years, the company has been working on the production of nylon fibre and CEO Giulio Bonazzi says that "without realising it we have always developed technologies that are very advanced in terms of environmental concerns… and looking at business in a circular way has opened up new opportunities for innovation.” Depolymerisation through the ECONYL® process is the next logical step for Aquafil. However, there is a tendency to overplay the link between ‘innovation’ and technology, when in fact the company is realising the benefits of a closed loop model right now, without relying on radical jumps in technology, or waiting for a revolutionary ‘silver bullet’ for the textiles industry.

We realised that Nylon 6 has these peculiarities, it can be depolymerised, and once this has been done with strong purification, then we can produce a product with exactly the same characteristics of the polymer coming from crude oil. We were lucky to be part of this system already, but we have invested money to develop technology that supports it.

- Giulio Bonazzi, CEO

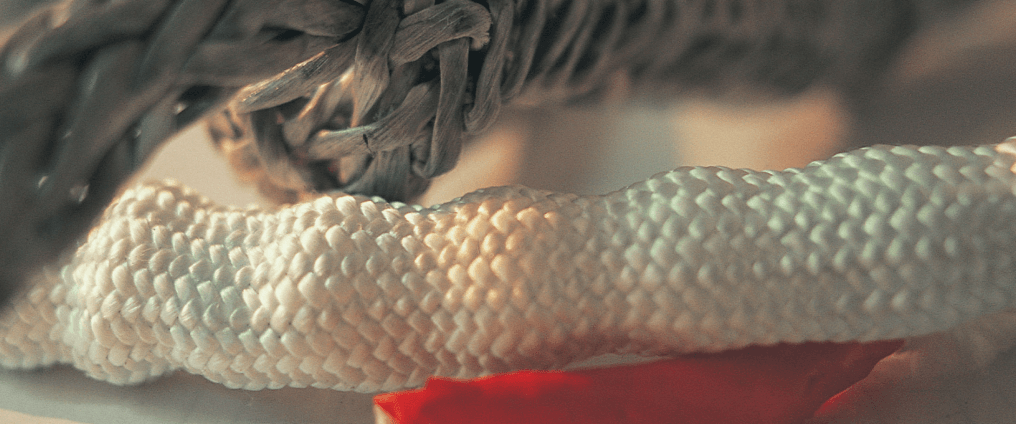

As Nylon 6 is already able to be depolymerised and re-polymerised with no loss of quality, the challenge has been accessing a reliable feedstock for this process. To this end, Aquafil established the ECONYL® Reclaiming Programme, an essential tool that the company is putting in place to facilitate a reverse supply chain and ensure reliable materials inputs. The programme sources a variety of products made entirely of Nylon 6, such as fishing nets, rigid fabrics or other plastic components. The company’s thinking has shifted – what used to be thought of as waste is now food for their industrial process.

For further information visit the ECONYL® website.

Photo credit: Joss Blériot