Global business has a key role to play in moving from an economy based upon a ‘take-make-dispose’ model to one based on a restorative and regenerative system. The linear model is reaching its physical limits: Recent data shows that in 2015, global demand for resources was equivalent to 1.5 times what Earth can support in one year.

At Google we believe in the democratizing effect of putting knowledge in the hands of everyone, so we are organising the world’s information and making it universally accessible. We are committed to doing that in a way that has a positive impact on the planet.

Published by Google and the Ellen MacArthur Foundation

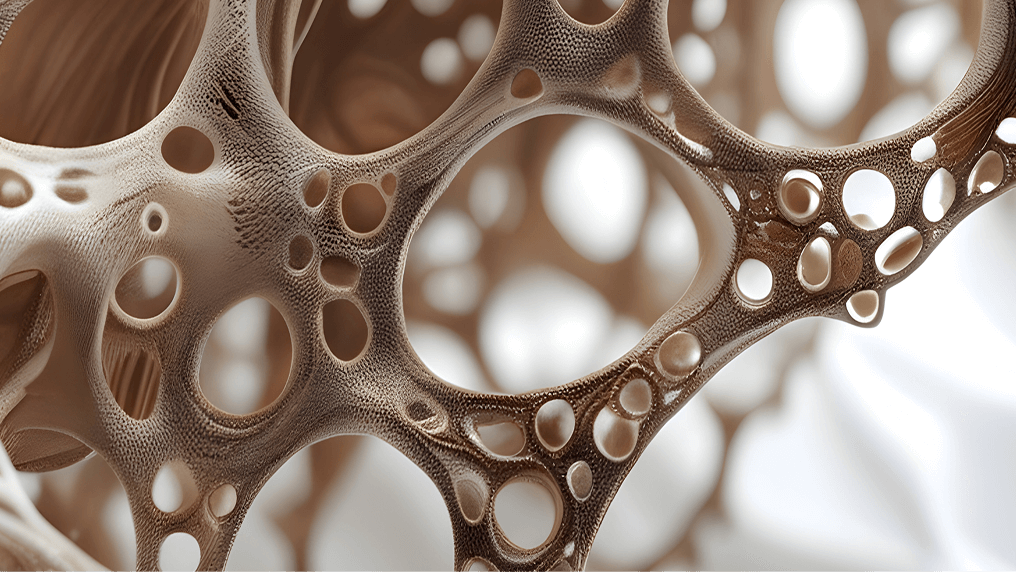

A circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature. is restorative and regenerative by design, and aims to keep products, components, and materials at their highest utility and value at all times. Key elements of the circular economy model optimise resources by circulating products, components and materials in use through different loops of the use cycle:

MaintainMaintainKeep a product in its existing state of quality, functionally and/or cosmetically, to guard against failure or decline. It is a practice that retains the highest value of a product by extending its use period. / Prolong

RefurbishRefurbishReturn a product to good working order. This can include repairing or replacing components, updating specifications, and improving cosmetic appearance. / RemanufactureRemanufactureRe-engineer products and components to as-new condition with the same, or improved, level of performance as a newly manufactured one.

ReuseReuseThe repeated use of a product or component for its intended purpose without significant modification. / RedistributeRedistributeDivert a product from its intended market to another customer so it is used at high value instead of becoming waste.

RecycleRecycleTransform a product or component into its basic materials or substances and reprocessing them into new materials.

Google’s global partnership with the Ellen MacArthur Foundation (Foundation) is supporting Google to build on existing practices and embed circular economic principles into the fabric of Google’s infrastructure, operations and culture.The Foundation works through education, business innovation and analysis to drive the acceleration of the transition to a circular economy.

There is no better example of how Google is implementing circular economy strategy at scale than how we manage the hardware inside our data centers. This case study reviews the practices we have implemented through maintenance, refurbishment/remanufacturing, redistribution/secondary market sales, and recycling. These practices combined with Google’s circular approach to optimizing end of life of servers based on Total Cost of Ownership (TCO) principles have resulted in hundreds of millions per year in cost avoidance.

Background

Google is always pushing for the most energy efficient, highest performing compute in every piece of hardware and square foot of our facilities. Our high performance computing is the result of optimization throughout our entire operation from the design of our servers to utilizing machine learning to squeezing the greatest efficiency out of our building systems. Google achieves high utilization of resources by sharingsharingThe use of a product by multiple users. It is a practice that retains the highest value of a product by extending its use period. machines through compute and storage shared services that serve all product areas (as opposed to each product area having its own dedicated machines). One such shared service for sharing compute capacity is Borg, an architecture for scheduling and managing applications across all Google data centers.

Much of our infrastructure is custom designed, from our own high voltage substations, to the on-site electrical distribution systems, to the proprietary cooling systems - all working in conjunction and optimized to provide the highest performance and lowest total cost of ownership computing infrastructure, saving Google over $1 billion in our operations through energy efficiency alone. Google servers don’t include unnecessary components such as video cards, chipsets, or peripheral connectors, which can introduce vulnerabilities. Server resources are dynamically allocated, allowing for flexibility in growth and the ability to adapt quickly and efficiently, adding or reallocating resources based on customer demand. Google optimizes server end-of-life based on TCO rather than industry standards for accounting life, which allows us to redeploy hardware based on remaining economic value rather than accounting book value. Google’s IP data network consists of our own fiber, peering, and undersea cables. This allows us to deliver highly available and low latency services across the globe but it also means we can respond faster to demand, providing capacity when needed.

Scope

This study encompasses machines (servers) and associated components (primary memory modules, hard disks and flash storage devices) in Google data centers and networking related equipment (fiber optics, switches and routers). We interviewed 15 individuals across 10 Google teams to understand the current practices in data center operations and supply chain. We analyzed this data to understand the scale and scope of current practices and what further opportunities can be explored to expand circular economy practices.

Circular economy practices at Google

Google’s supply chain for servers (Product) consists of components that make a server including: CPU, Motherboard, Flash Devices, Hard Disks, Memory Modules and other components. Since Google manages the manufacturing and assembly operations of its custom built servers, Google is the Product Manufacturer in Google’s server supply chain.

Each quarter Google performs an Excess and Obsolescence (E&O) process, which analyzes the life cycle stage of components and their total cost of ownership relative to new hardware, and matches demand and supply to determine E&O levels. A key outcome of the E&O process is component disposition. There are three main dispositions:

Inventory - refurbished components are put back in inventory

Resale / remarket - any excess component supply is sold on the secondary market

Recycle - materials are recycled

Multiple programs and processes within Google’s Data Center Operations and Supply Chain groups apply key circular economy strategies including:

Maintain / Prolong:

Google’s repairs process at the data centers enables longer life expectancy of the servers. As servers fail and fall into repairs, defective parts are replaced by refurbished parts, which enables longer usage of parts. Hard drives/ disks and memory modules (DIMMs) are the most commonly repaired (replaced) components. The repairs program replaces failed components using a mix of new and refurbished parts.

In 2015, 75% of components consumed in the spares program were refurbished inventory.

Refurbish / Remanufacture:

Once servers from data centers are decommissioned, they are sent back to the central hub. At the hub servers are dismantled and de-kitted to their usable components (CPU, motherboard, Flash devices, hard disks, memory modules and other components). After quality inspection, components are stored to be reused as refurbished inventory.

Google custom builds its own servers for data centers through a program called the Servers Build program. Refurbished parts (mentioned above) are used to build remanufactured servers and are then deployed back into data centers. In Google data centers, there is a mix of the servers running the latest technology platforms and also older platforms. Once components are in inventory, there is no distinction made between refurbished and new inventory, both are considered equivalent.

In 2015, 19% of servers Google deployed were remanufactured machines. There are two other programs where Google uses refurbished parts:

Server Upgrades

The Server Upgrades program is a process by which the useful life of servers can be prolonged by upgrading aging (not effective) technology (components) in the servers. Primary components that are upgraded in servers are hard disks/drives, memory modules (DIMMs) and flash devices (SSD). Components that come out of the servers due to the upgrade are also sent back to the warehouse and are reused by putting them back into inventory.

Spares and Repairs

The Spares and Repairs program is a process for repairing of servers and components as they fail in the data center. In 2015, 52% of components consumed in Machine Upgrades program were refurbished inventory.

Reuse / Redistribute:

Google redistributes any excess component inventory as determined by quarterly E&O process internally. After utilizing all internal avenues Google goes through a rigorous process to ensure no proprietary Google technology resides on the components before selling on the secondary market. Google works in close collaboration with selected remarketing partners to look at various market factors for resale. There are three primary components that are resold on the secondary market: memory modules, hard drives and OEM Networking equipment.

In 2015, Google resold nearly 2 million units into the secondary market for reuse by other organizations.

Recycle:

Google maximizes the recycling of all data center material, including the electronic equipment that leaves our data centers. Hard drives and storage tapes that cannot be resold are crushed and then shredded. These crushed materials along with plastics and metals from other electronic waste are then combined and sent to a recycling partner for secure processing and recycling into reusable materials.

Google data center server operations - circular economy

Principle 1

Preserve and enhance natural capital by controlling finite stocks and balancing renewable resource flows ReSOLVE levers: regenerate, virtualise, exchange

Principle 2

Optimise resource yields by circulating products, components and materials in use at the highest utility at all times in both technical and biological cycles ReSOLVE levers: regenerate, share, optimise, loop

Principle 3

Foster system effectiveness by revealing and designing out negative externalities All ReSOLVE levers

Conclusion

Google is–– practicing the concepts of circular economy in our servers supply chain and is unlocking the value that comes from demonstrating the circular economy at scale. As part of the Google-wide circular economy program we will continue to explore other opportunities throughout data center operations. It is Google’s belief that doing so will yield additional value for business, partners and users.

Download this case study

Circular economy at work in Google data centers is available in English