The Upstream Innovation guide tells how to harness the power of upstream innovation as a root-cause solution to plastic waste.

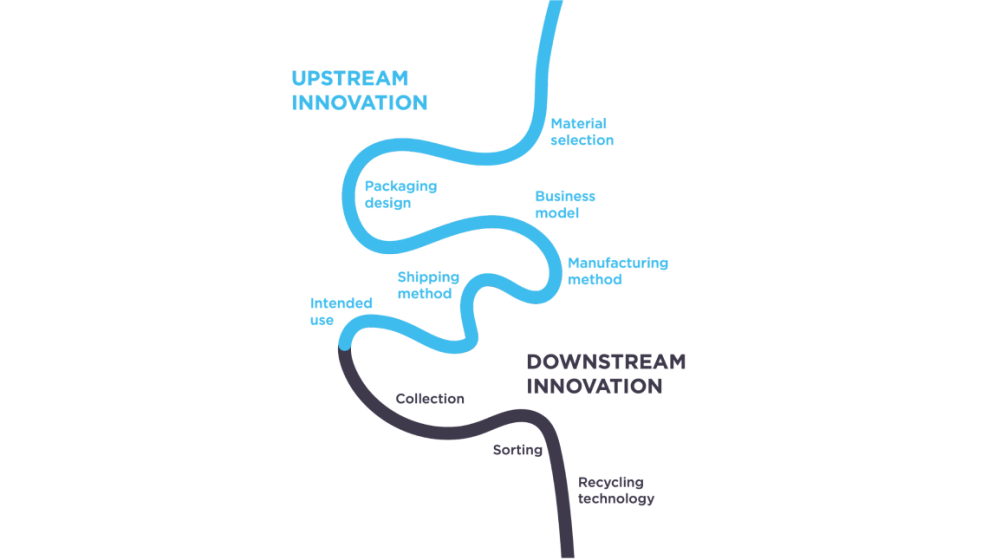

What is upstream innovation?

In a circular economycircular economyA systems solution framework that tackles global challenges like climate change, biodiversity loss, waste, and pollution. It is based on three principles, driven by design: eliminate waste and pollution, circulate products and materials (at their highest value), and regenerate nature., upstream innovation is about tracing a problem back to its root cause and tackling it there. It means that rather than working out how to deal with a pile of waste, we prevent it from being created in the first place. Find out how moving upstream can tackle packaging waste and pollution while generating economic benefits.

Upstream Innovation: Rethinks products and services at the design stage. For example, this can include developing new materials, product designs, or business models.

Downstream Innovation: Affects a product or material after its first use. For example, this can include developing a new collection, sorting, and recycling technologies.

This guide focuses on upstream.

Why consider upstream innovation?

Tackle plastic waste and pollution

By redesigning products, materials, and services, it is possible to prevent waste from being created in the first place.

Example: Coca-Cola’s reuse model for PET bottles operating in Latin America, prevents the production of 1.8 billion single-use bottles per year.

Provide the solutions customers want

Plastic pollution has attracted widespread public attention, and customers increasingly reward brands that deliver real solutions — on plastics and beyond.

Example: In 2018, Unilever’s Sustainable Living Brands* grew 69% faster than the rest of the business, delivering 75% of the company’s growth.

Capture untapped business opportunities

Finding new ways of delivering products while designing out waste can lead to business benefits, such as cost savings, brand loyalty, and user convenience

Example: Shifting just 20% of plastic packaging from single-use to reuse is an upstream innovation opportunity estimated to be worth USD 10 billion.

Reduce carbon emissions

Many solutions that design out waste also design out carbon emissions.

Example: SodaStream (acquired by PepsiCo in 2018), which enables customers to make sparkling water at home, reduces carbon emissions by up to 87% compared to sparkling water sold in single-use plastic bottles.

Get ahead of changing regulation

Governments around the world are adopting legislation targeted at tackling plastic waste.

By embracing the power of upstream innovation, companies can stay ahead of the curve.

Join the new normal

Through the Global Commitment and Plastics Pact network, more than 1,000 organisations, including companies responsible for over 20% of all plastic packaging globally, have united behind the Foundation’s common vision for a circular economy for plastic, with a strong upstream innovation component.

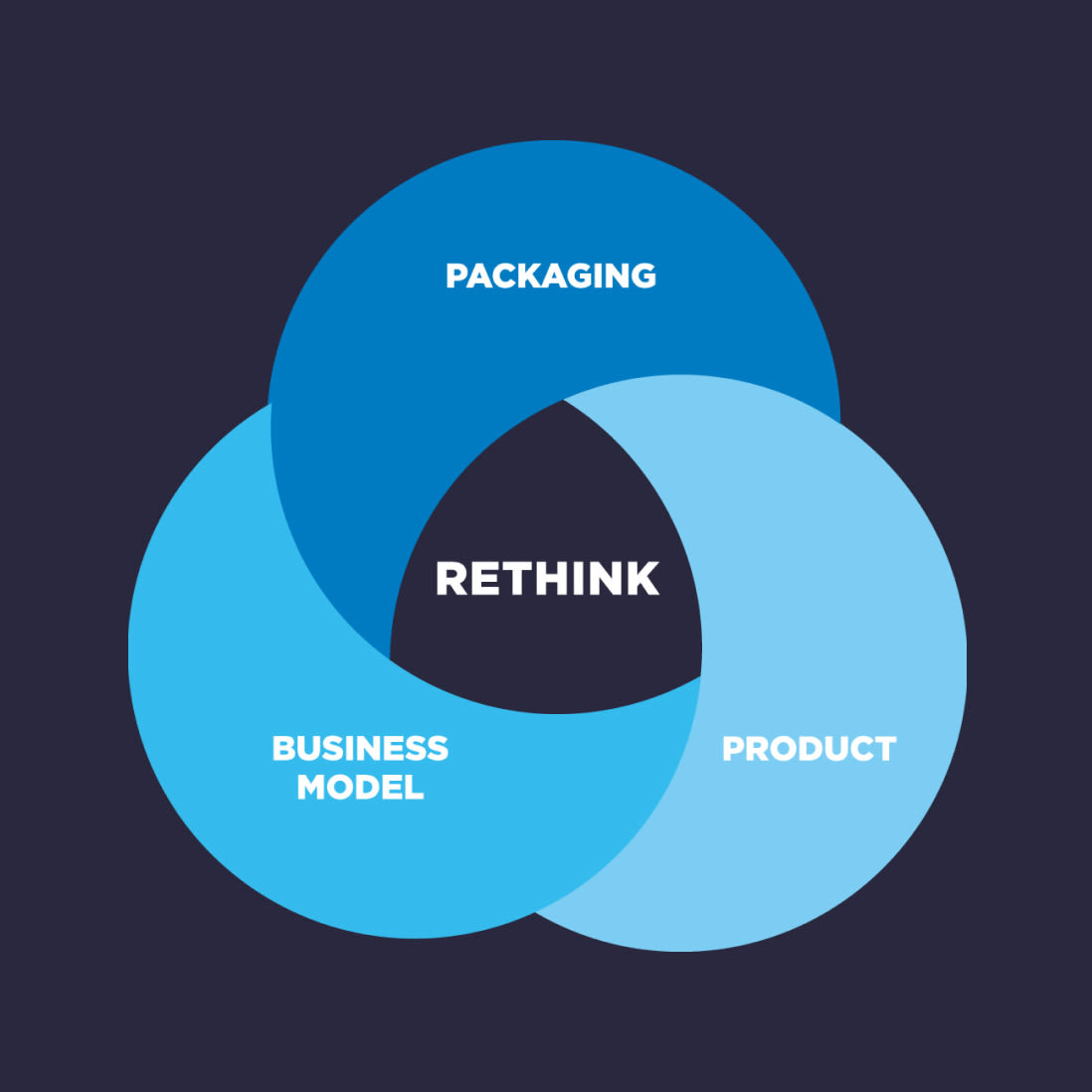

The mindset

Rethinking the packaging, product, and business model to prevent and design out packaging waste

Upstream innovation requires a shift in mindset, beyond focusing on incremental packaging improvements. It is about rethinking how we get products and services to users without creating waste.

Rethinking the packaging

Rethinking the packaging means innovating at the packaging design level (packaging concept, format, components, material choice) to provide the same essential packaging function, while designing out waste. For example, moving from non-recyclable to recyclable packaging formats or using a completely different type of material.

Rethinking the product

Rethinking the product means innovating at the product design level (product formulation, concept, shape, size) to change the packaging needs, while maintaining or improving the user experience. For example, changing from a physical product to a digital product, or from a liquid product to a solid product.

Rethinking the business model

Rethinking the system means innovating at the system design level (business model, supply chain, location of production, product delivery) to change the packaging needs. For example, selling products in refillable or returnable packaging, rather than single-use packaging. Localising production, so freshness can be assured without relying on the complex, often less recyclable packaging, that is frequently required in global supply chains.

The three strategies

The upstream innovation mindset can be used to achieve three key circular economy innovation strategies — elimination, reuse, and material circulation. Backed by more than 110 innovation case examples, we show what good looks like in practice.

Making it happen

There are five key ingredients that underpin successful upstream innovation efforts:

1. Company-wide vision and targets

Publicly communicate a long-term vision (e.g. by signing the Global Commitment or joining a Plastics Pact). Set targets to trickle down and become core objectives for individuals and departments.

Example: Tesco’s 4R strategy (remove, reduce, reuse and recycle) was set out by the Tesco Group CEO at four meetings with over 1,500 suppliers. Targets were established to remove 1 billion pieces of packaging by the end of 2020.

2. Intrapreneurial culture

Support a culture of intrapreneurship. To succeed with upstream innovation, organisations need internal change agents — intrapreneurs — with ideas that push the boundaries, and who see ways to create better products or reach new markets, even when it conflicts with existing business priorities. This can be done by, for example, allocating time for employees to work on projects of personal interest or hosting development programmes and competitions to support and accelerate idea generation.

Example: Nestlé’s InGenious crowdsourcing platform helps employees collaborate and grow ideas into tangible opportunities. Since its launch, employees have created 6,400 new ideas and submitted 92,000 votes.

3. External input

Bring in external complementary assets, resources, skills, and expertise when required. This can be achieved by establishing partnerships with start-ups, hiring consultancies to fill internal knowledge gaps, or getting feedback from NGOs.

Example: Partnering with NGOs for input and feedback was key to the successful innovation process to develop the reusable universal bottle for Coca-Cola Latin America.

4. Breaking silos

Actively seek to break organisational silos and foster collaboration across teams and business units. Set up a core team of internal champions who are responsible for securing business wide buy-in, as well as capturing and sharing learnings.

Example: To develop the reusable universal bottle in Latin America, Coca-Cola formed an agile team with senior representation from marketing, finance, commercial, quality, and technical areas, helping to get fast company-wide buy-in.

5. Patient capital

Ensure there is a well-funded innovation process with room to fail and patience for return on investment. Patient capital can come in many forms, including the allocation of internal funding, external investment into impact funds, research and development grants, or human resources — but common to all, is patience and the understanding that truly transformative innovation takes time.

Example: Nestlé has established a CHF 250 million sustainable packaging venture fund to invest in start-up companies focusing on circular economy.

Through in-depth interviews and extensive engagement with businesses, we have identified five key ingredients that support a successful upstream innovation process in the corporate setting. It is not necessary for all key ingredients to be present all the time, but the presence of at least a few does appear to mean the innovation process is more likely to be successful.

Read how the five key ingredients contributed to four successful innovations on p. 166 in the guide. Here you will also find additional guidance on making upstream decisions and the role of Life Cycle Assessment (LCA) in upstream innovation.

To quote this study, please use the following reference: Ellen MacArthur Foundation, Upstream Innovation: A guide to packaging solutions (2020).

Download the full guide

Want to explore the opportunity of upstream innovation with others?

Get started with our free, customisable design tools and resources